What Torque Should I Use For Screws . — using a screwdriver, a minimum torque of 30 n m can be achieved. torque is the only value usable for deciding the quality of screw joints. Screws are usually rated for a specific tightening. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. The longer the lever, the greater the force that can be applied. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. torque is the rotational force applied to the fastener to create tension and secure the joint properly. The torque, or the moment of force, can be measured either dynamically, when.

from templates.hilarious.edu.np

torque is the rotational force applied to the fastener to create tension and secure the joint properly. Screws are usually rated for a specific tightening. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. torque is the only value usable for deciding the quality of screw joints. The torque, or the moment of force, can be measured either dynamically, when. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. The longer the lever, the greater the force that can be applied. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. — using a screwdriver, a minimum torque of 30 n m can be achieved.

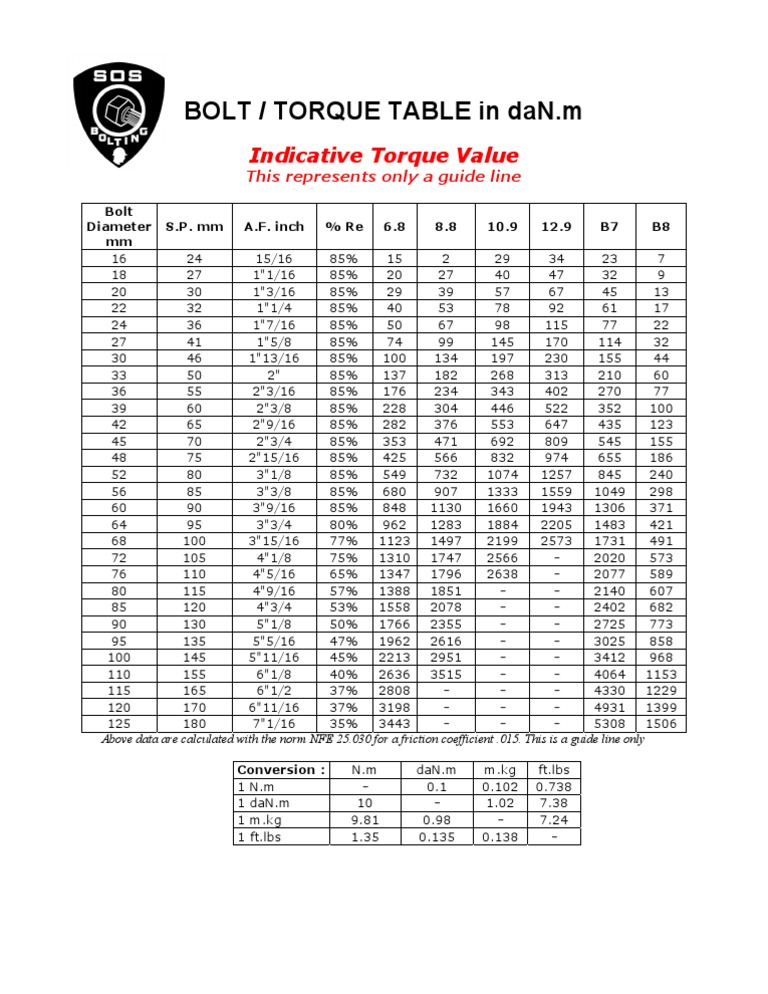

Printable Bolt Torque Chart

What Torque Should I Use For Screws — finding the maximum tightening torque for most common types of screws and bolts is an important first step. Screws are usually rated for a specific tightening. torque is the only value usable for deciding the quality of screw joints. The longer the lever, the greater the force that can be applied. The torque, or the moment of force, can be measured either dynamically, when. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. — using a screwdriver, a minimum torque of 30 n m can be achieved. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. torque is the rotational force applied to the fastener to create tension and secure the joint properly. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry.

From www.sampletemplates.com

Bolt Torque Chart 7 Free PDF Download Sample Templates What Torque Should I Use For Screws torque is the only value usable for deciding the quality of screw joints. — using a screwdriver, a minimum torque of 30 n m can be achieved. Screws are usually rated for a specific tightening. torque is the rotational force applied to the fastener to create tension and secure the joint properly. The torque, or the moment. What Torque Should I Use For Screws.

From www.sampletemplates.com

FREE 7+ Sample Bolt Torque Chart Templates in PDF, Word What Torque Should I Use For Screws torque is the only value usable for deciding the quality of screw joints. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. Screws are usually rated for a specific tightening. The longer the lever, the greater the force that can be applied. — 1 nm. What Torque Should I Use For Screws.

From mungfali.com

Standard Bolt Torque Chart Fastener Torque Specifications Bolts 973 What Torque Should I Use For Screws torque is the only value usable for deciding the quality of screw joints. Screws are usually rated for a specific tightening. torque is the rotational force applied to the fastener to create tension and secure the joint properly. — using a screwdriver, a minimum torque of 30 n m can be achieved. The torque, or the moment. What Torque Should I Use For Screws.

From www.autozone.com

Repair Guides Fasteners, Measurements And Conversions Measuring What Torque Should I Use For Screws — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. — finding the maximum tightening torque for most common types of screws and bolts is an. What Torque Should I Use For Screws.

From engineerfix.com

What Is Torque? Definition, Where It Is Used, and FAQs What Torque Should I Use For Screws Screws are usually rated for a specific tightening. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. The torque, or the moment of force, can be measured either dynamically, when. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared. What Torque Should I Use For Screws.

From www.sstls.com

What is the torque specifications for machine screws? What Torque Should I Use For Screws — finding the maximum tightening torque for most common types of screws and bolts is an important first step. The torque, or the moment of force, can be measured either dynamically, when. The longer the lever, the greater the force that can be applied. — when a screw or bolt is lubricated, less torque is needed to achieve. What Torque Should I Use For Screws.

From www.zerofast.com

Proper Bolt Torque zero products inc. What Torque Should I Use For Screws torque is the rotational force applied to the fastener to create tension and secure the joint properly. Screws are usually rated for a specific tightening. The torque, or the moment of force, can be measured either dynamically, when. The longer the lever, the greater the force that can be applied. — using a screwdriver, a minimum torque of. What Torque Should I Use For Screws.

From www.accu.co.uk

Tightening Torques For Machine Screws Accu What Torque Should I Use For Screws — using a screwdriver, a minimum torque of 30 n m can be achieved. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. torque is the rotational force applied to the fastener to create tension and secure the joint properly. — 1 nm is. What Torque Should I Use For Screws.

From blog.roninsgrips.com

How To Find Out Torque Specifications for Screws and Bolts An What Torque Should I Use For Screws — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. torque is the rotational force applied to the fastener to create tension and secure the joint properly. . What Torque Should I Use For Screws.

From fixengineukusniju88.z22.web.core.windows.net

Torque Specifications For Bolts What Torque Should I Use For Screws The longer the lever, the greater the force that can be applied. The torque, or the moment of force, can be measured either dynamically, when. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. — using a screwdriver, a minimum torque of 30 n m can be achieved.. What Torque Should I Use For Screws.

From repairfixanemi5b.z4.web.core.windows.net

Torque Chart For Bolts Sizes What Torque Should I Use For Screws torque is the rotational force applied to the fastener to create tension and secure the joint properly. torque is the only value usable for deciding the quality of screw joints. Screws are usually rated for a specific tightening. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't. What Torque Should I Use For Screws.

From www.repairengineering.com

Bolt Torque Chart What Torque Should I Use For Screws — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. torque is the rotational force applied to the fastener to create tension and secure the joint properly. The torque, or the moment of force, can be measured either dynamically, when. — using a screwdriver, a minimum. What Torque Should I Use For Screws.

From www.youtube.com

Torque + Angle Tools benefits YouTube What Torque Should I Use For Screws — finding the maximum tightening torque for most common types of screws and bolts is an important first step. torque is the rotational force applied to the fastener to create tension and secure the joint properly. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. Screws. What Torque Should I Use For Screws.

From exozhuony.blob.core.windows.net

Standard Set Screw Torque Chart at Jose Gomez blog What Torque Should I Use For Screws The torque, or the moment of force, can be measured either dynamically, when. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. — using a screwdriver, a minimum torque of 30 n m can be achieved. The longer the lever, the greater the force that can be. What Torque Should I Use For Screws.

From repairfixmenyeid50.z4.web.core.windows.net

Standard Torque For Bolts Metric What Torque Should I Use For Screws — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. torque is the rotational force applied to the fastener to create tension and secure the joint properly. The torque, or the moment of force, can be measured either dynamically, when. — using a screwdriver, a minimum. What Torque Should I Use For Screws.

From www.accu.co.uk

Tightening Torques For Machine Screws Accu What Torque Should I Use For Screws — using a screwdriver, a minimum torque of 30 n m can be achieved. — finding the maximum tightening torque for most common types of screws and bolts is an important first step. — 1 nm is too much torque for standard pcb material to handle before cracking if your screws don't strip. Screws are usually rated. What Torque Should I Use For Screws.

From www.autozone.com

Repair Guides What Torque Should I Use For Screws The longer the lever, the greater the force that can be applied. torque is the only value usable for deciding the quality of screw joints. — when a screw or bolt is lubricated, less torque is needed to achieve the desired tension compared to a dry. torque is the rotational force applied to the fastener to create. What Torque Should I Use For Screws.

From www.pinterest.ca

fastener torque charts Bolt, Chart, Work tools What Torque Should I Use For Screws — finding the maximum tightening torque for most common types of screws and bolts is an important first step. torque is the only value usable for deciding the quality of screw joints. Screws are usually rated for a specific tightening. — 1 nm is too much torque for standard pcb material to handle before cracking if your. What Torque Should I Use For Screws.